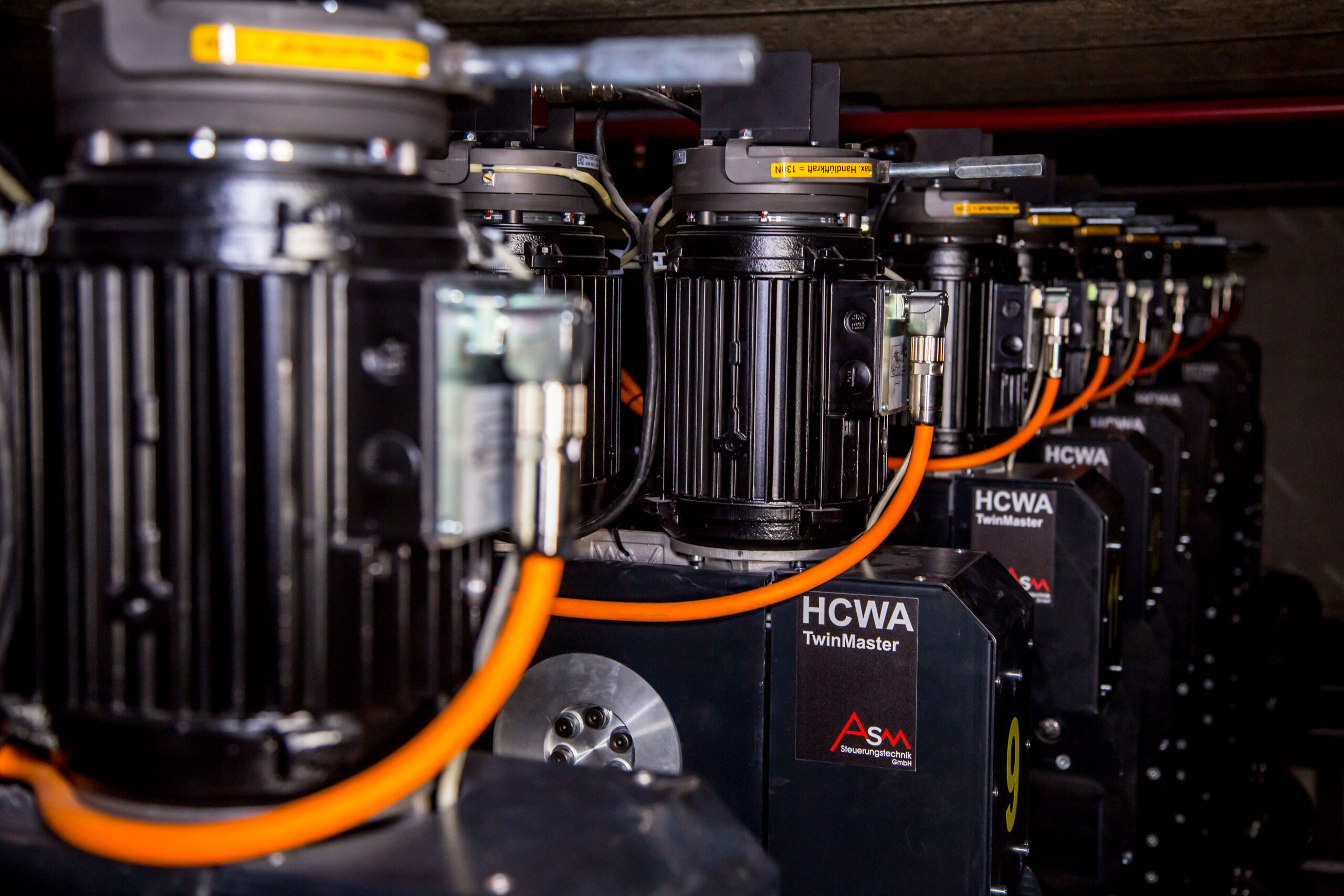

HCWA TwinMaster Family

“HCWA TWINMASTER, A UNIQUE PRODUCT WITH NO EQUAL”

Originally designed to effortlessly replace the manual theatre counterweight system, ASM engineers designed the impressive HCWA TwinMaster series with a slim design of less than 200 mm. The completely redundant hoist is driven by the patented double worm gear by means of extremely durable steel band, which ensure particularly smooth and silent running of the rope drum. All HCWA TM come with two independent silent theatre brakes.

Depending on model, each hoist has a standard lifting capacity up to 1000 kg and a fixed or variable speed up to 2,0 m/s*. Travel of up to 34 meters is possible*.

The HCWA TM range feature a silent noise level of only 45 dB(A)1m. It is 50% lighter than other scenery hoists, reducing forces on existing stage structures.

As the scenery hoist is driven by two independent motors, the reduction gear operates on two channels and thus offers maximum safety. The HCWA TM is designed in strict conformity with the DGUV V17 and EN 17206 regulations. Above that, the HCWA scenery hoist has a gearbox integrated safety catch and safety standards that are unique in the market. The HCWA range has been developed to allow installation to conform local and international safety regulations and in combination of almost all professional controls.

The HCWA TM hoist is mechanically completely redundant which offers a solution in countries where high torque brakes are required by national regulations.

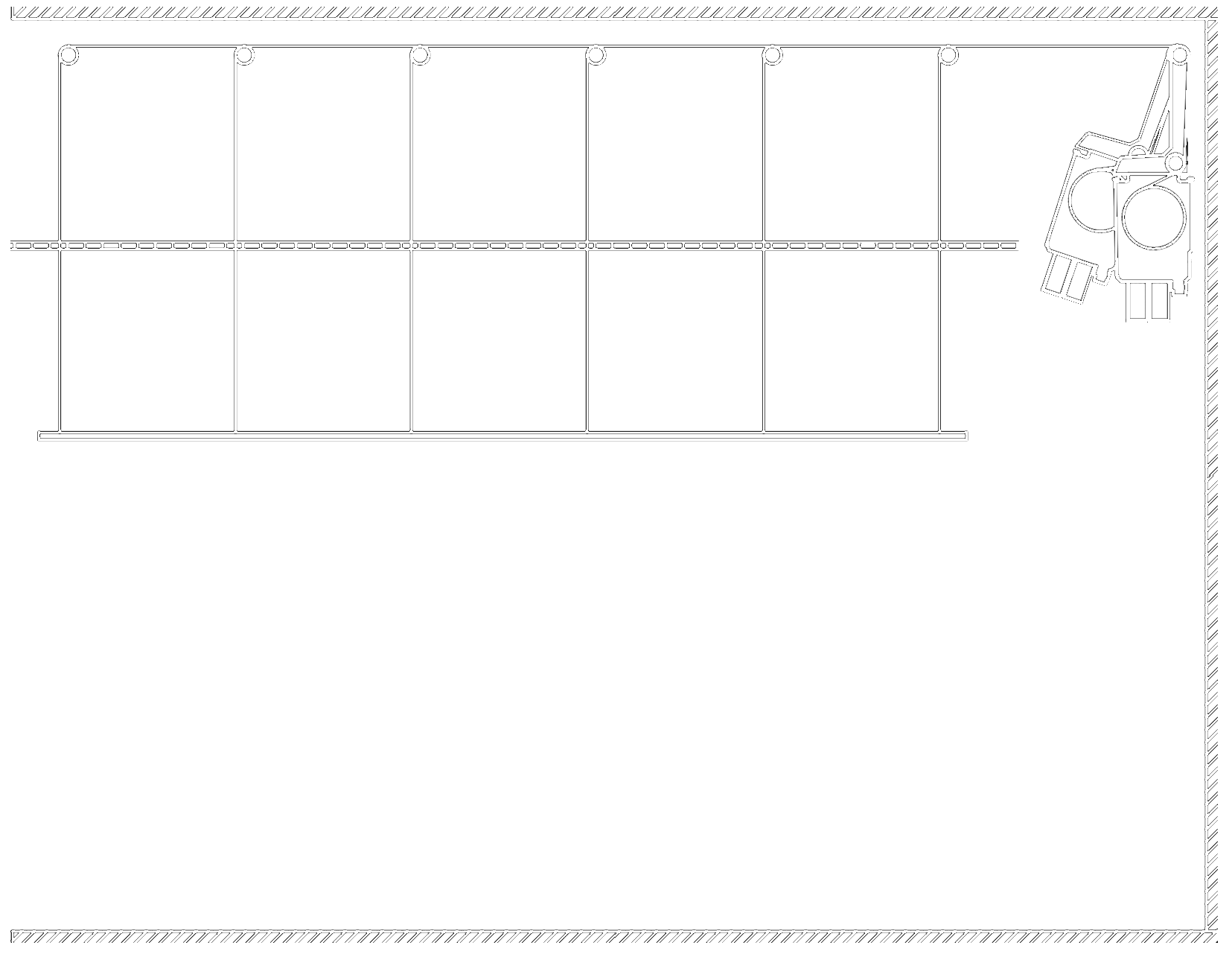

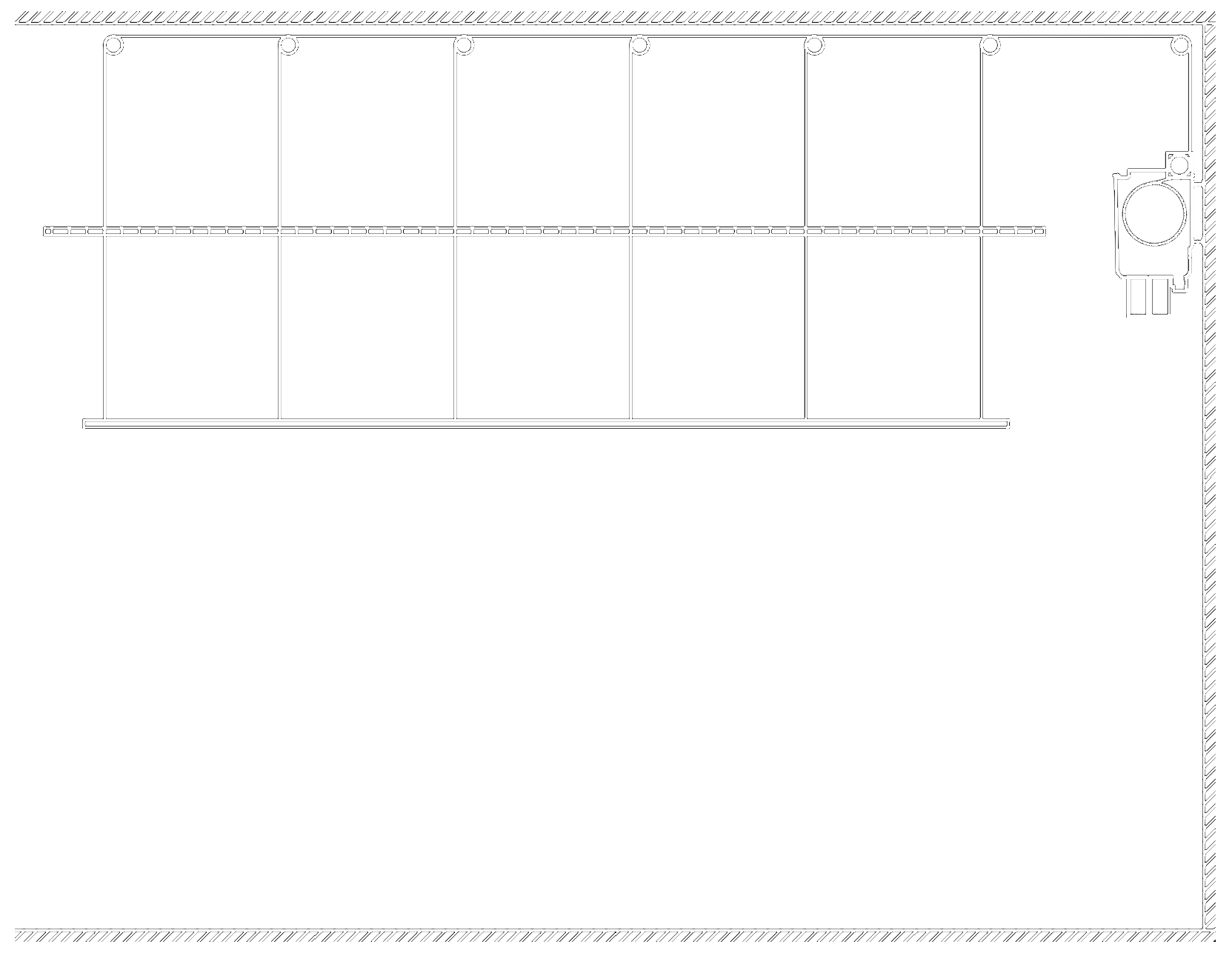

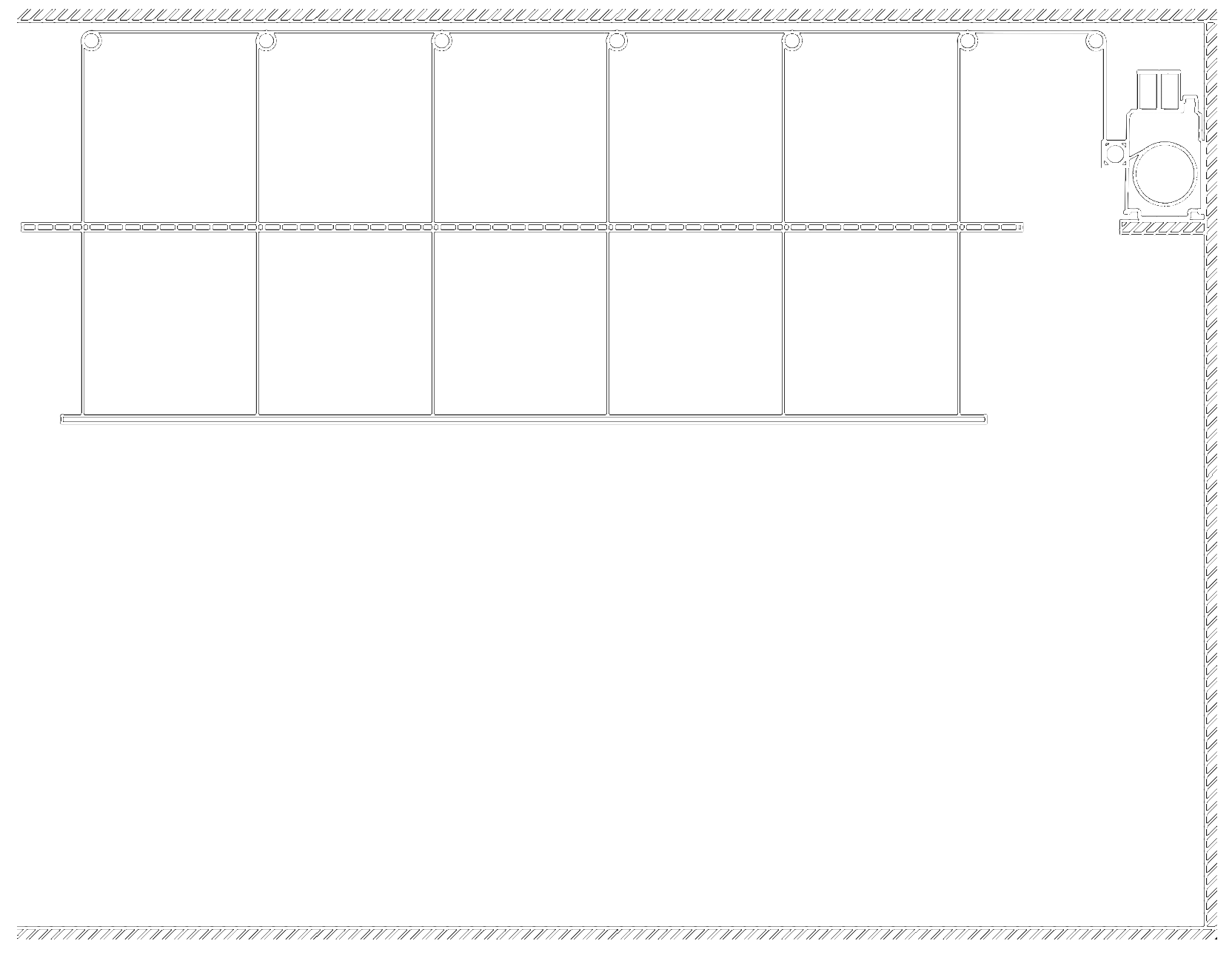

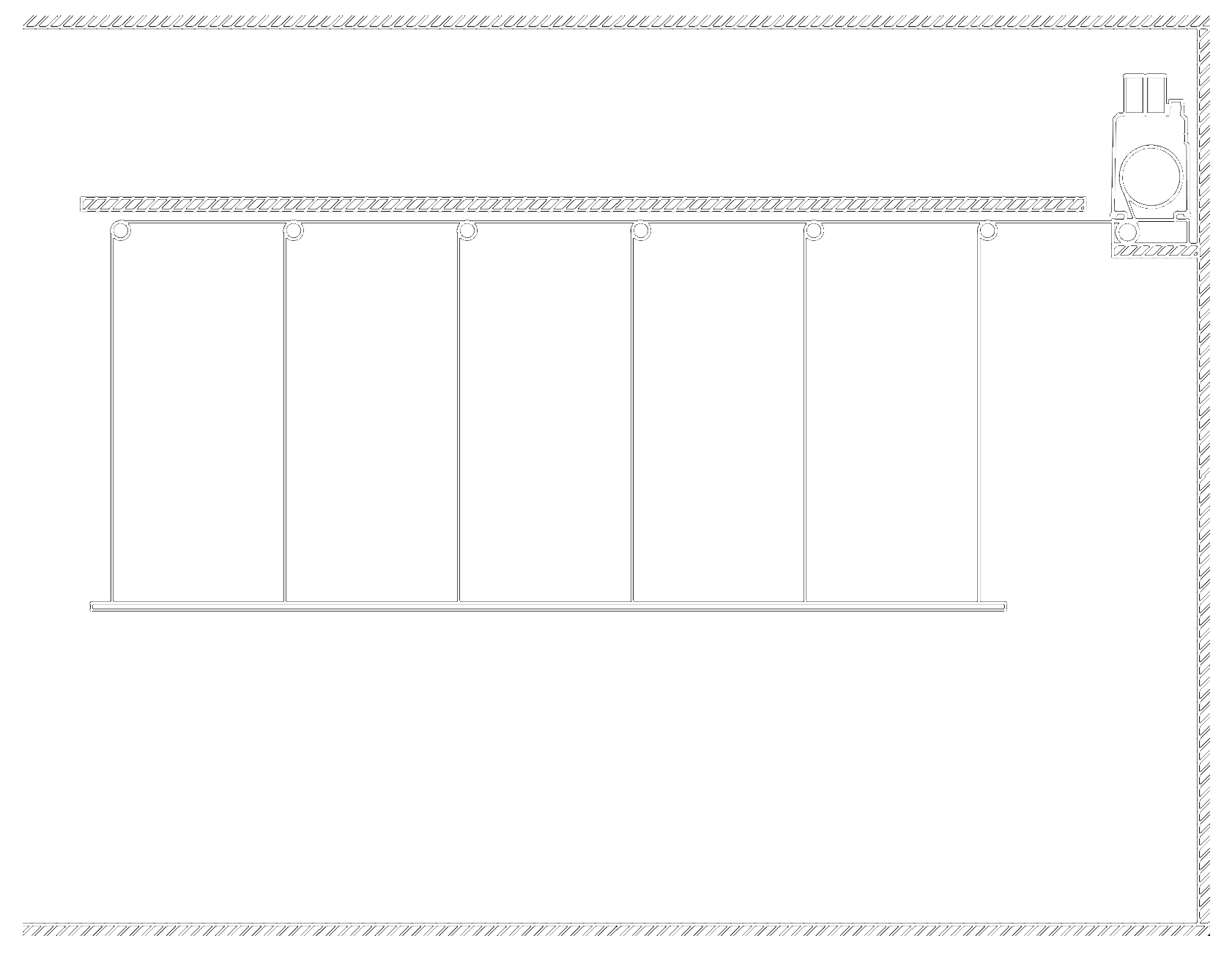

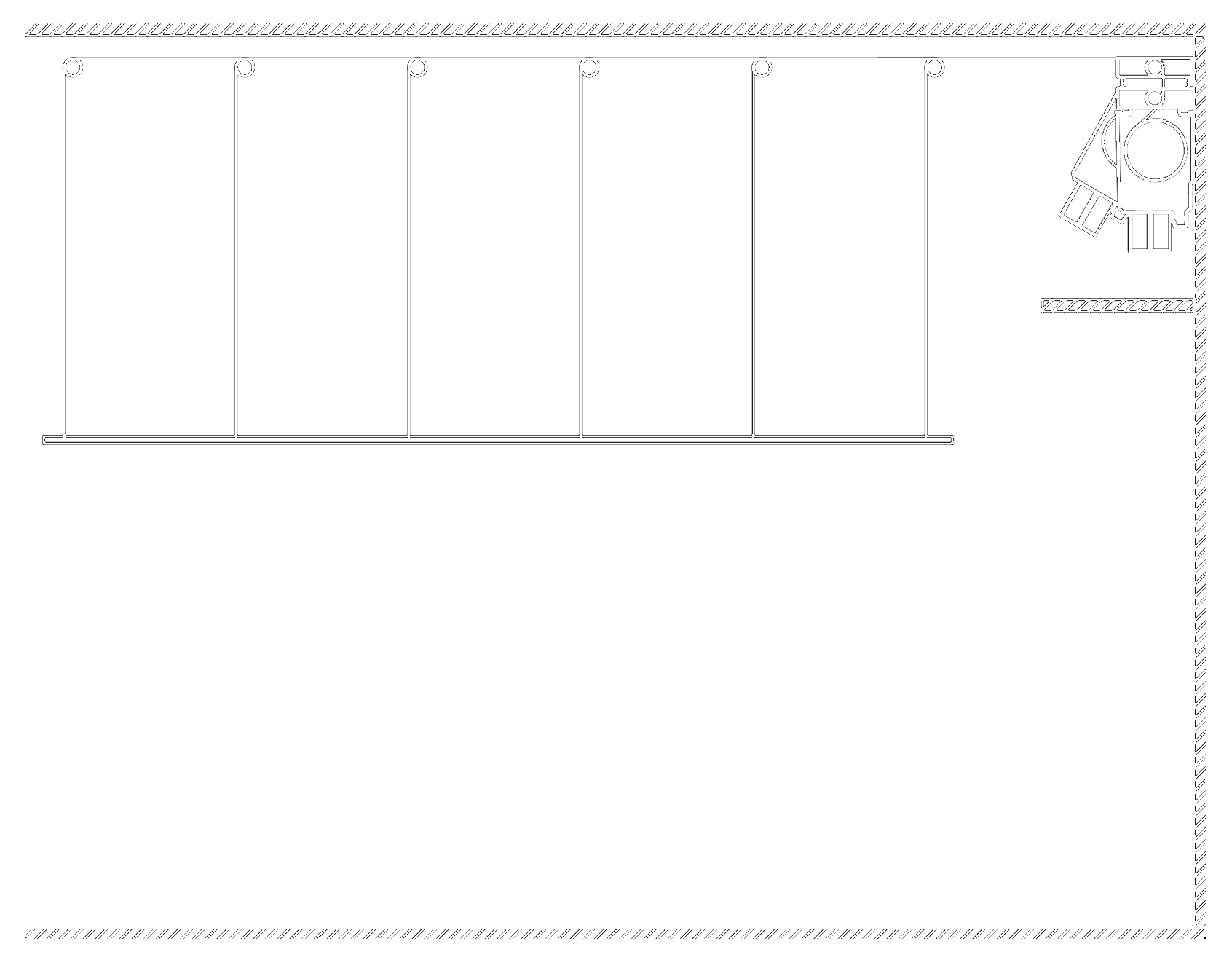

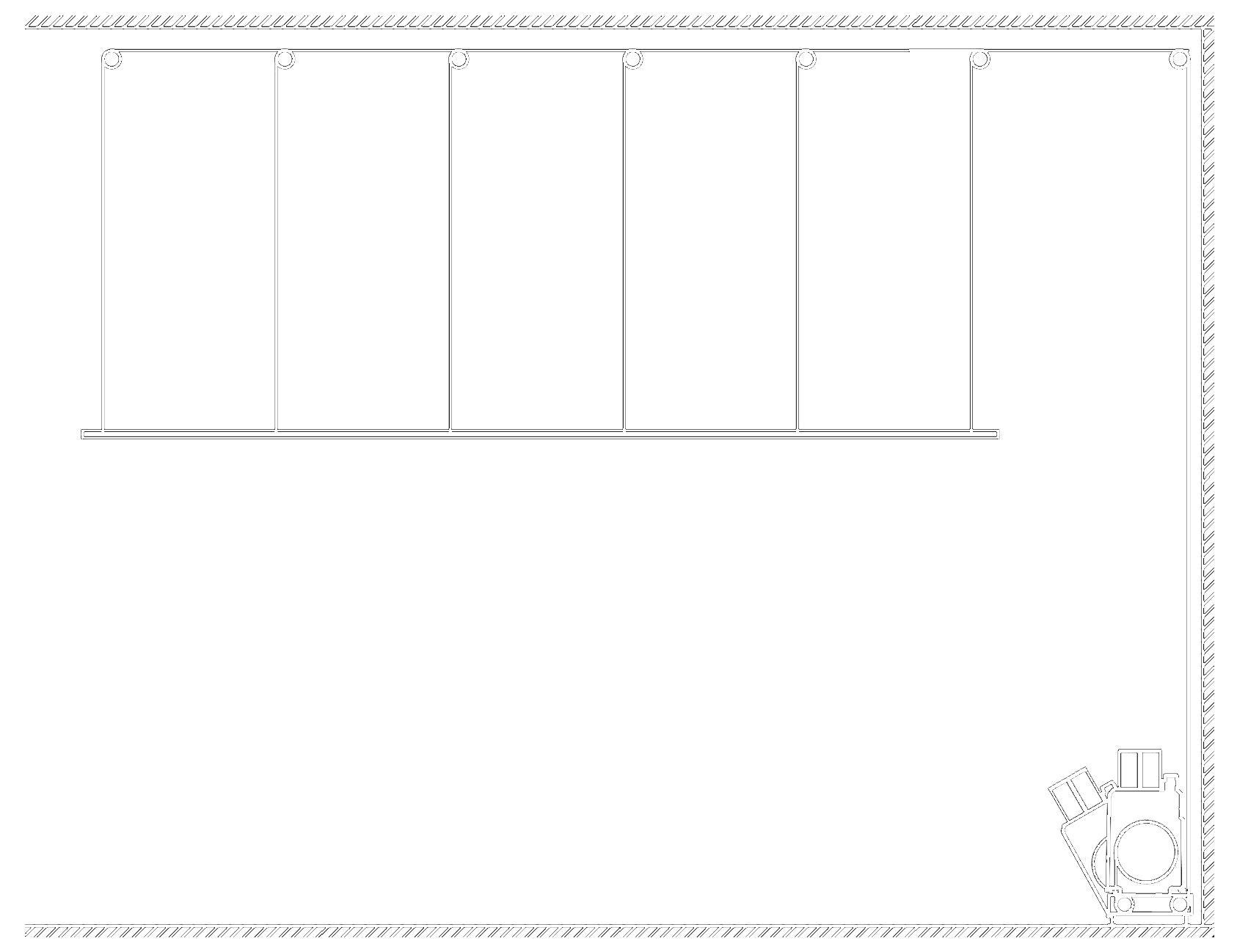

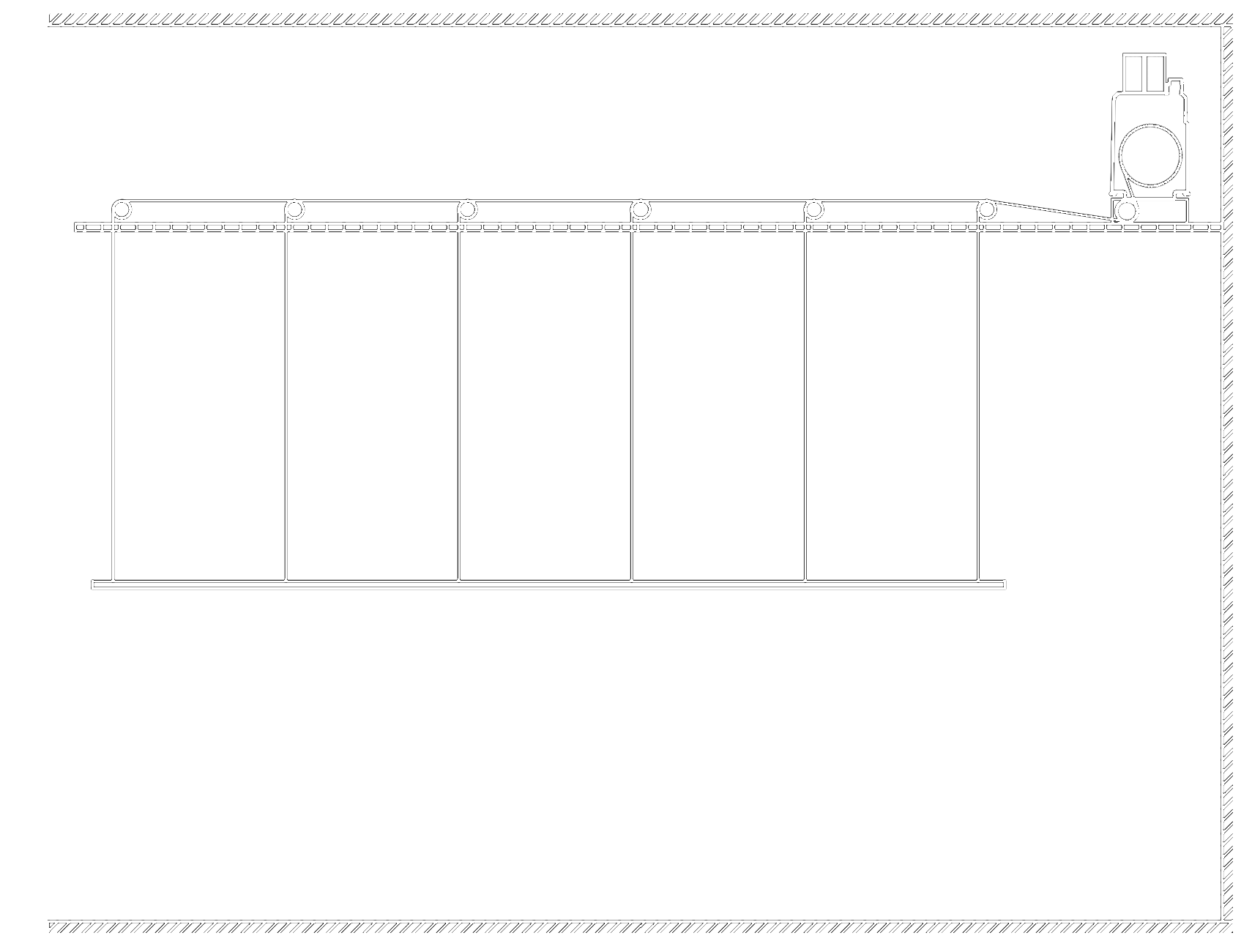

The HCWA TM scenery hoist has not only proven to be a magnificent space saver on fly loft installations, but it allows flexible hanging on head pulley structures or on wall installations. The HCWA TM hoist is designed for flexible installations positions. Mechanical coupling of two hoists is possible.

All HCWA hoists are made to be SIL 3 ready and can be coupled with a SIL3 control, such as ASM GENESIS SIL3 control.

* Other speeds, lifting capacities and travel on request

STANDARD FEATURES & BENEFITS

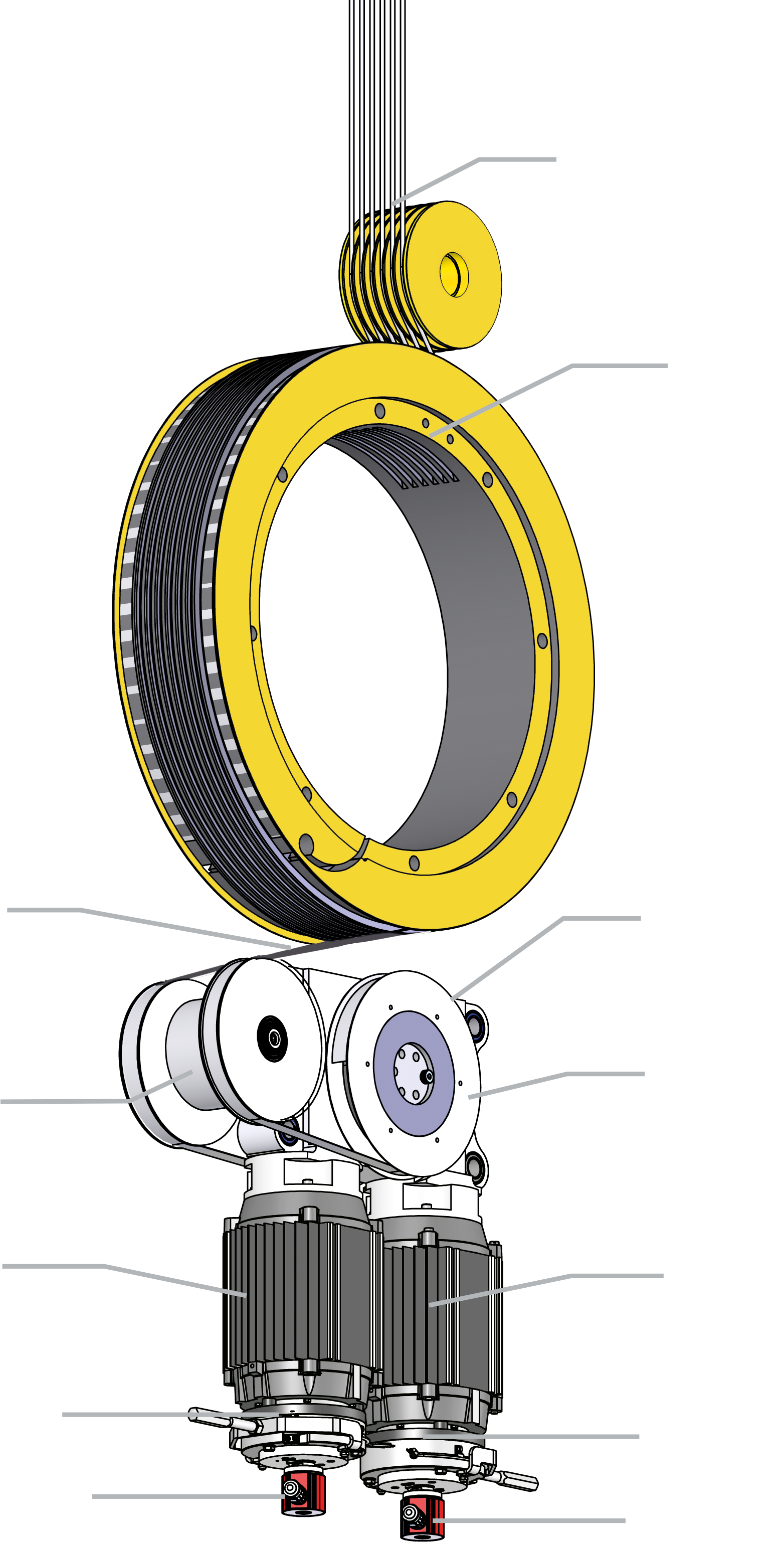

- Redundant, two channel safety hoist concept with international patented double worm gear with safety catch.

- International patented drive (steel band gear) of the rope drum by means of two extremely durable steel bands.

- The international patented balancer evenly distributes the load transmission on both bands (50/50).

- The hoist consists of a rope drum unit and a motor unit mounted on ultrasonic vibration dampers, resulting in the elimination of noise, vibration and swing in the chassis.

- Zero fleet hoist. No interfering rope angles.

- The hoist features a gearbox with a safety catch, which sets a superior safety standard in the market.

- High precision positioning of the load is achieved due to large drum diameter.

- Pile wind drum inside of a particularly high-quality cast polyamide drum.

- The steel frame inside the cast polyamide drum prevents drum collapse in event of a fire.

- Extremely silent and smooth-running of ropes due to cast polyamide drum is ensured (long life expectancy)

- The standard drum consists of 7 groves (more groves on request). In case of less, the groves will be filled up by ASM. The groves can always be reopened in a later stadium.

- Ropes are inserted and crimped inside the steel frame of the drum and securely fixed with quick links in the steel drum housing. This attachment of the ropes ensures full safety without extra safety turns (according to EN 17206)

- Rope pulleys and rope drum are yellow according to German regulations (black ones available on request)

THE HCWA TM RANGE

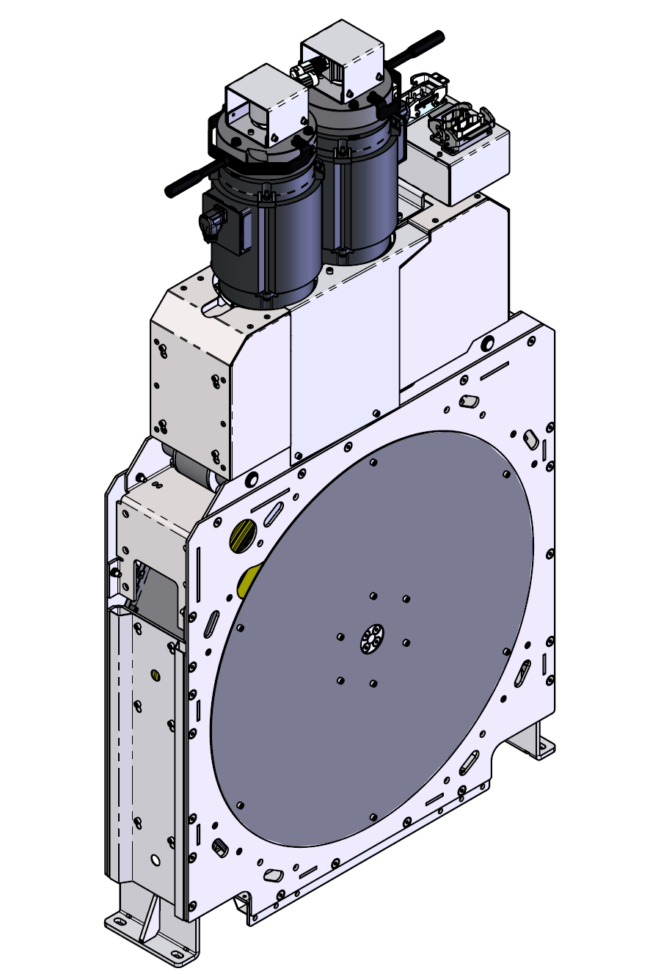

The HCWA TM hoist is composed of 2 main assemblies, the drum and the drive unit in different sizes depending on the model.

The standard drums in different diameters come with 7 grooves for 6 mm ropes, for a total width of the hoist of less than 200mm.

If less ropes are needed, ASM or the approved partner will close the extra grooves professionally, which can be reopened later.

If more ropes are needed optional extra grooves are possible. Beware that the total width of hoist will be more than 200 mm.

The HCWA TM drive unit consists mainly of the HCWA TM redundant double worm gearbox, two motors, two theatre brakes, two encoders and the balancer.

HCWA TM RANGE

All with 6 mm ropes & 7 drops

| Available drum diameter | Speed* in m/s | Total hoist capacity** in kg | ELL in kg | Loadbar in kg | |||

|---|---|---|---|---|---|---|---|

| HCWA TM | Drive 108 | 8 kW (2x4kW) | 600/700/800 | 1 | 650 | 500 | 150 |

| 1,2 | 550 | 400 | 150 | ||||

| 1,5 | 450 | 300 | 150 | ||||

| HCWA TM | Drive 211 | 11 kW (2×5,5 kW) | 800/1000 | 1,2 | 750 | 550 | 200 |

| 1,5 | 600 | 450 | 150 | ||||

| 1,8 | 500 | 350 | 150 | ||||

| HCWA TM | Drive 215 | 15 kW (2×7,5 kW) | 800/1000 | 1,2 | 850 | 650 | 200 |

| 1,5 | 800 | 650 | 150 | ||||

| 1,8 | 700 | 500 | 200 | ||||

| HCWA TM | Drive 218 | 18,4 kW (2×9,2 kW) | 800/1000 | 1,2 | 1000 | 800 | 200 |

| 1,5 | 900 | 700 | 200 | ||||

| 1,8 | 800 | 600 | 200 | ||||

*In case the standard hoist is requested with a faster speed, the individual case needs to be reviewed by ASM. Beware that the load capacity of the hoist is reduced.

**The max. load capacity of the hoist can be limited if less numbers of ropes are used.

As ASM engineered each hoist to their fullest capacity, each model has their specific composition which cannot be altered. Special models can be offered on request.

| Model: | Max travel in m*(6 mm rope)**: |

|---|---|

| HCWA TM 600 | 17,5 |

| HCWA TM 700 | 21 |

| HCWA TM 800 | 24,5 |

| HCWA TM 1000 | 31 |

*The max travel comes without an extra safety turn, but with enough rope to allow the dead end function. In case you still require them, please contact ASM or your ASM partner for the max. travel with safety turn.

** Longer travel or 8 mm ropes on request

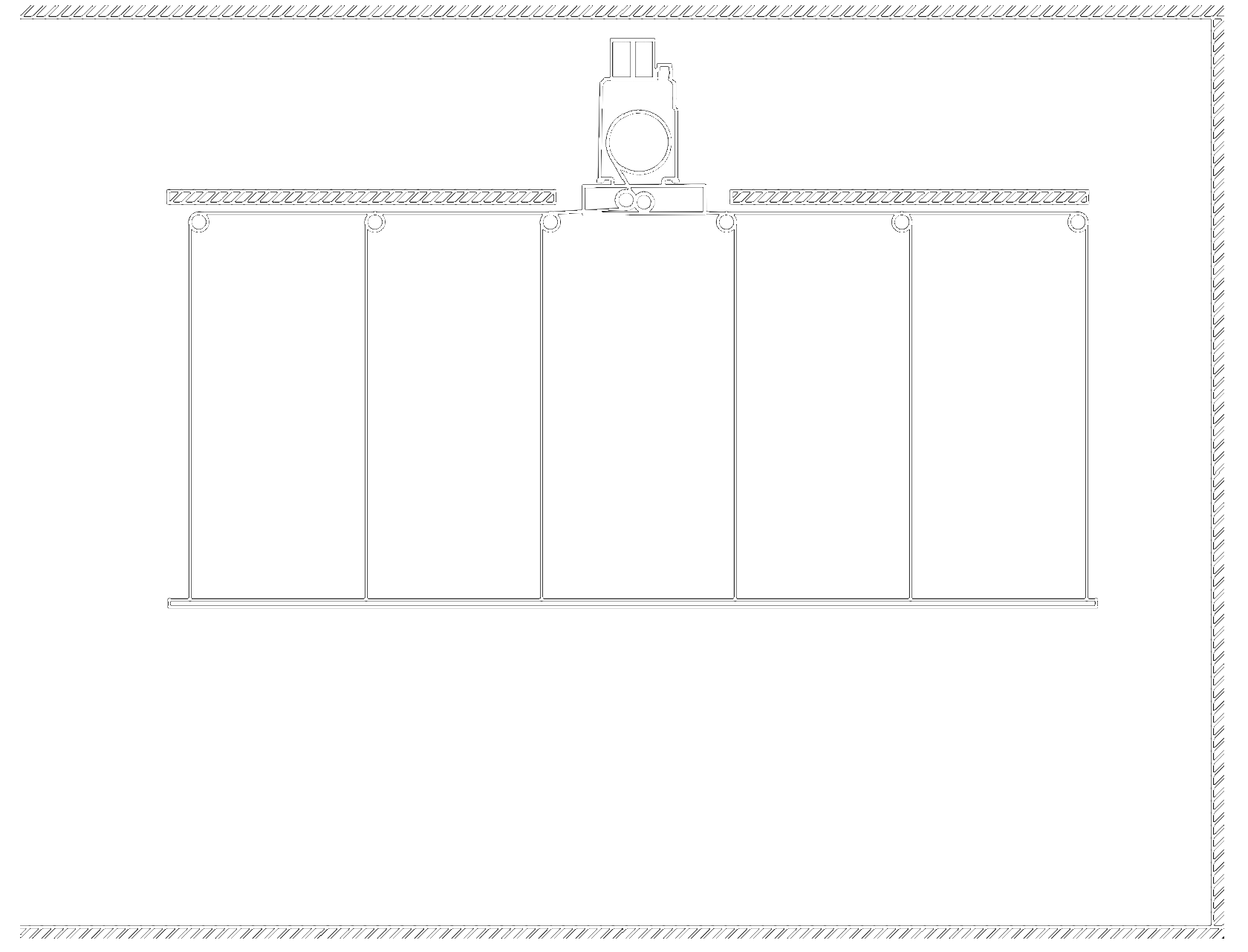

METHODS OF INSTALLATION